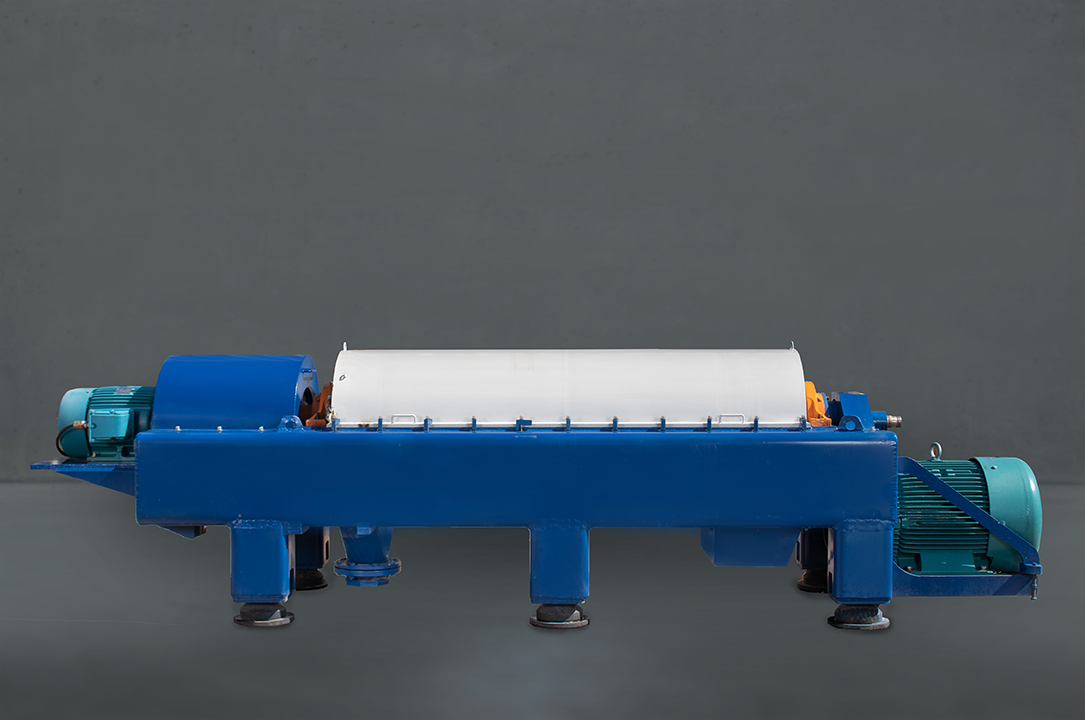

Decanter centrifuge for solids control

Applications:

For drill solids removal, high-speed separation, barite recovery, system de-weighting, and ultrafines removal.

Optimizing drilling fluids:

The 2183 Decanter Centrifuge is a key component in a top-quality solids control process. This unit efficiently removes most of the fine particles that traditional solids control equipment cannot catch. Built for heavy-duty jobs, the 2183 Decanter Centrifuge handles large amounts of feed solids as well as being able to cope with abrasive and coarse particles.

The GREYSON 2183 drilling fluids decanter is available in the PERMIAN BASIN through SKYHOOK SERVICES who are located in Midland, Texas.

Take advantage of the 2183 Decanter Centrifuge technology

- Torque control

- Greater solids recovery

- Higher G-Force

- Increased centrate clarity

- More efficient particle separation

- Specially designed bowl geometry

- Various power pack designs to suit the operation

- Reduced waste volumes

- A 360-degree solids outlet completes the concept

Principle of operation

2183 Decanter Centrifuge features a slender cylindrical/conical bowl with a relatively large length/diameter ratio. The screw conveyor, which is fitted inside the bowl, enables the continuous removal of separated solids.

Technical data

Maximum hydraulic flow rate*: Max.speed with:

Maximum speed Centrifugal force Differential speed range Solids capacity

Main power

Back Drive

Dry weight decanter unit

Operating weight 5,500 kg (11,110 lbs)

100 m3/h (440 GPM)

(1,800 kg/m3 wet solids) 3,300 rpm (2,900 G) (2,500 kg/m3 wet solids) 2,800 rpm (2,100 G) 3,650 rpm

up to 3,574 G

2-40 rpm

up to 12 ton/h (26,000 lbs / h)

90 kW (125 Hp)

15 kW (20 Hp)

5,000 kg (11,000 lbs)

* The operating flow rate depends on the individual properties of the feed and the separation result required.